Combinatorial Chemistry

Combinatorial Deposition Systems

Overview

Technology has advanced through taking advantage of material properties to address practical problems. As technology needs becomes more complex, there is a corresponding need for more efficient ways to discover materials that are “fit-for-purpose”. That is, the question being asked is not “what can we do with this material?” but rather “how can we discover a material that meets an identified need?”

Combinatorial chemistry – also referred to as high throughput materials discovery or high throughput experimentation –accelerates materials discovery by making large numbers of samples with differing compositions and rapidly screening them for effectiveness in an application. For example, battery materials for electric vehicles must provide high energy density for long range power, while simultaneously seeking to eliminate critical metals such as nickel and cobalt. At the same time, lightweight yet strong alloys for automobile bodies can serve to reduce the power needed from those batteries.

The challenge in discovering these materials lies in their complexity. High entropy alloys (HEA) are an example of an active field of research, holding out great promise for materials with applications at high temperature, in difficult corrosive environments, in areas where light weight and high strength must be combined, for high hardness, and for energy storage – to give a partial list. HEA’s are defined as having at least five elements in their composition, each with a significant atomic fraction. The number of possible HEA’s then rises into the billions, based on this requirement. Clearly, a one-sample-at-a-time approach will not suffice to explore such a large composition space.

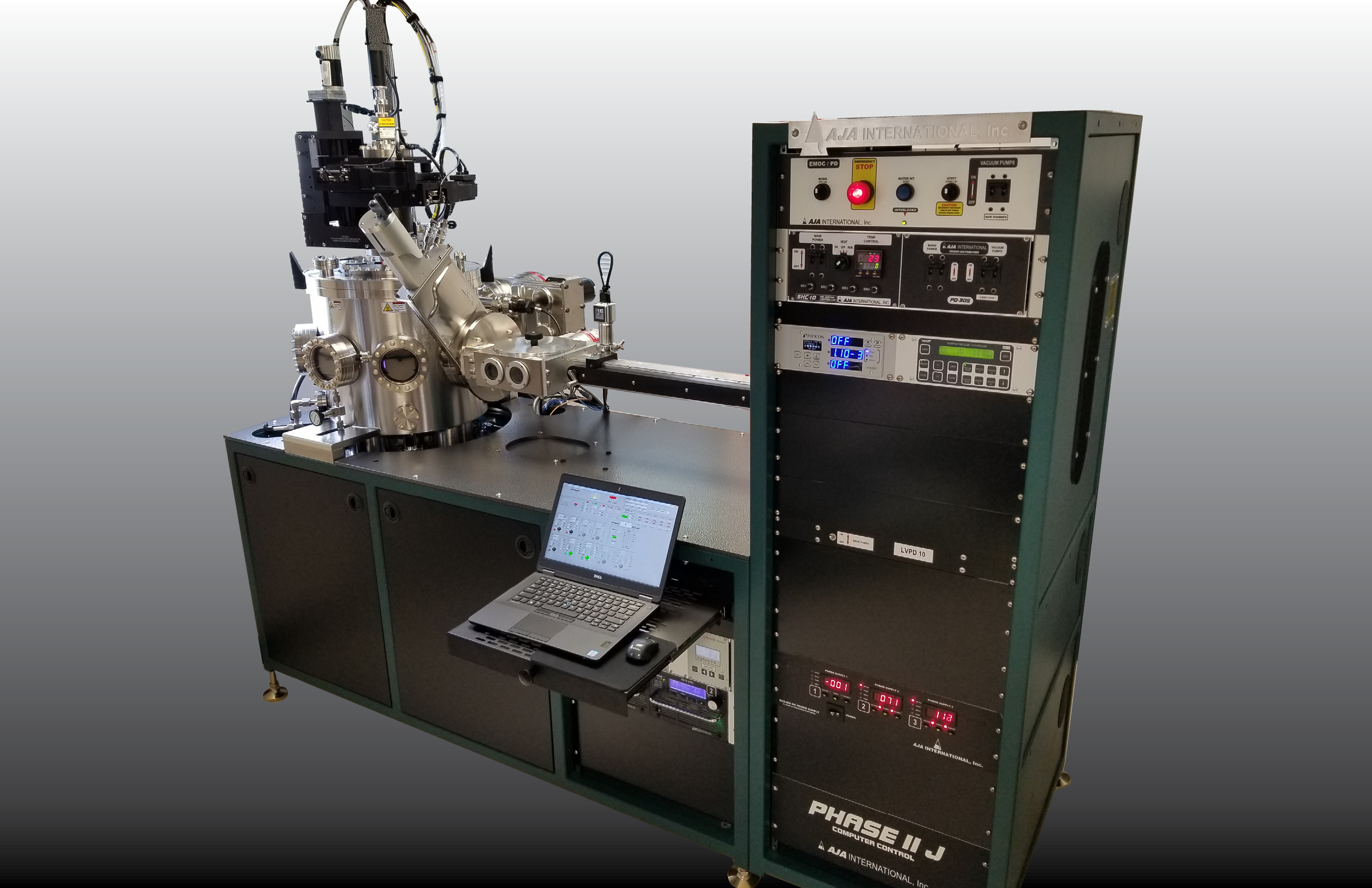

This is where high throughput experimentation – and AJA International’s solutions – come into play. Our combinatorial deposition tools offer the ability to make a large number of thin film samples in one run on a single substrate using a masking system with a step-and-repeat process – or multiple substrates if using a cassette loader. Continual composition gradient films are also possible. The system can be designed for substrates up to 200 mm in diameter. Multiple magnetrons can co-sputter to make practically any desired composition. Testing, in-situ in or after the samples are removed, can rapidly screen many sample spots for optimal properties.

Key Features of AJA Combinatorial Deposition Systems

AJA International offers a range of deposition platforms configured for advanced combinatorial materials research. These systems support a variety of deposition techniques—including magnetron sputtering, electron beam evaporation, and hybrid configurations—designed to meet the complex demands of academic and industrial R&D environments.

Magnetron Sputtering Sources:

Our systems commonly feature in-situ tiltable magnetron sputtering sources, allowing angular adjustment without breaking vacuum. This enables precise control over compositional gradients and film uniformity across discrete samples – or the entire substrate surface, if blanket films are required. Optimizing gun array patterns support the systematic fabrication of binary, ternary, quaternary or higher complexity compound libraries – up to the number of guns and power supplies available. This flexibility is critical for high-throughput materials discovery and optimization.

Combinatorial Substrate Holder:

AJA’s combinatorial substrate holders build upon our robust standard designs and are enhanced with UHV-compatible X/Y stepper motor-driven bellows mechanisms. These holders accommodate multiple discrete samples on a single substrate, with common configurations including 5×5 and 10×10 arrays of 5 mm specimens (25 and 100 samples, respectively).

An integrated automated masking system—with interchangeable apertures—allows flexible specimen sizing and isolation. The mask assembly can be retracted for gradient film deposition or traditional confocal sputtering geometries with azimuthal substrate rotation for uniform coatings. All substrate holders are compatible with high-temperature heating (up to 1000°C), RF/DC biasing, and cryogenic cooling (LN₂ or H₂O), enabling a wide range of process conditions.

Power Supply Configurations:

AJA systems support an extensive suite of power delivery options tailored to diverse materials and process requirements. Available configurations include DC, RF, pulsed DC, and high-power impulse magnetron sputtering (HiPIMS).

Load-Lock and Sample Transfer Systems:

To support varying levels of throughput, AJA provides flexible load-lock solutions, including both manual and fully automated sample transfer systems. For high-throughput screening, cassette-based modules are available to accommodate 2 to 10 carriers. Optional pre-processing modules—such as sample pre-cleaning, degassing, surface oxidation, and in-situ diagnostics—can be integrated to enhance process efficiency and reproducibility.

In-Situ Analytical Capabilities:

Our combinatorial platforms are designed for integration with a broad range of in-situ analytical tools to enable real-time process monitoring and film characterization. Compatible diagnostics include reflection high-energy electron diffraction (RHEED), ellipsometry, optical emission spectroscopy (OES), pyrometry, and residual gas analysis (RGA), providing researchers with the data needed to understand and control film growth at the atomic level.

4” wafer with 5x5 matrix, allowing up to 25(5mm) individual samples with varying stoichiometry

6” wafer with radial pattern allowing up to 24(5mm) individual samples with varying stoichiometry

8” wafer with 10x10 matrix, allowing up to 100(5mm) individual samples with varying stoichiometry

6” wafer with gradient film

Performance

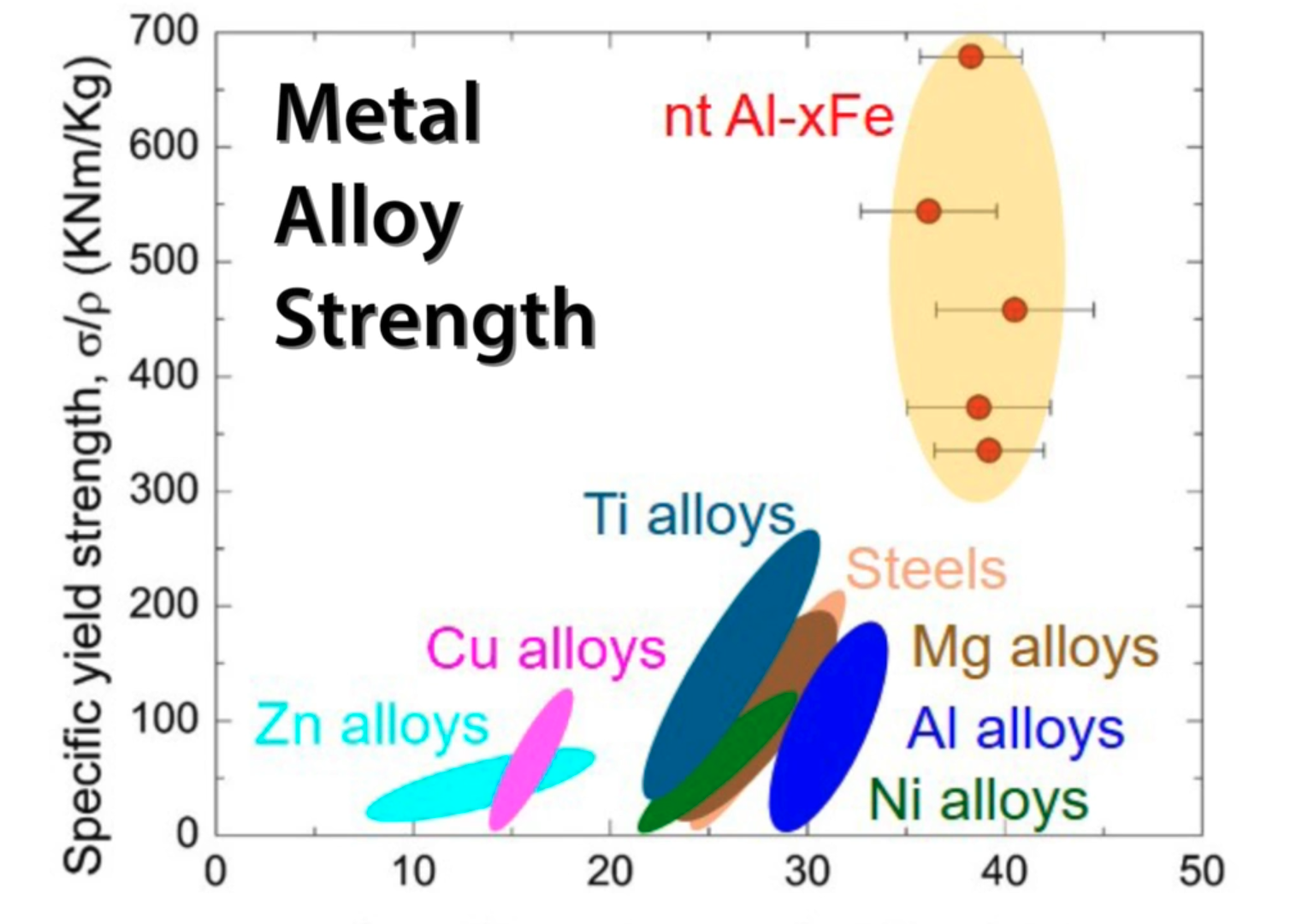

In a landmark study demonstrating the power of combinatorial chemistry, Professor Xinghang Zhang and his research team at Purdue University developed a significantly stronger aluminum alloy—one with mechanical properties approaching those of stainless steel, yet retaining aluminum’s low weight and corrosion resistance.

At the foundation of this research was the use of AJA International’s advanced thin film deposition equipment. The team leveraged AJA’s magnetron sputtering systems to precisely alloy aluminum with iron, enabling the creation of nanostructured coatings with controlled twin boundaries—features critical to achieving the exceptional strength and ductility observed in their samples.

Alongside this, the researchers used shock-loading techniques to induce rare structural phases in ultrathin aluminum films, further improving performance. The controlled combination of alloying and defect engineering resulted in the formation of a rare 9R phase—a crystal structure that’s difficult to achieve in aluminum, but essential for enhancing its mechanical properties.

The ability to tune material properties at the nanoscale using AJA’s flexible deposition platforms was instrumental in realizing these results. This work not only opens up new possibilities for high-performance aluminum alloys in aerospace, automotive, and protective coatings, but also showcases how state-of-the-art equipment enables cutting-edge innovation in materials science.

Professor Zhang’s research stands as a strong example of how combinatorial chemistry, empowered by precise thin film technology, can unlock entirely new classes of materials for real-world applications.

Read more on Professor Zhang’s work here:

AJA International’s Combinatorial Deposition Systems offer a powerful solution for high-throughput materials research. These advanced platforms enable deposition of discrete thin film arrays or continuous compositional gradients on substrates up to 200 mm. Featuring in-situ tiltable magnetron sources, motorized substrate holders, and integrated masking, they deliver precise control over film composition and uniformity. Compatible with high-temperature heating, cryogenic cooling, and in-situ analytics, these systems are ideal for rapid materials discovery and process optimization.

To learn how AJA can support your research, contact our sales team today.