Hybrid

Coating Systems

Versatile tools that combine processes.

AJA International ATC-M Series Hybrid Systems are versatile tools that combine various thin film deposition, ion milling and analytical operations in a single chamber (Hybrid Systems) to allow the in-situ transfer of substrates from process to process without breaking vacuum.

These systems can be built in HV or UHV configurations, and in either cylindrical or box chamber styles.

Magnetron Sputtering

E-Beam Evaporation

Thermal Evaporation

Ion Milling

Ion Beam Deposition

Pulsed Laser Deposition

Ellipsometry

Rapid Thermal Anneal

Multi-Techniques employed include:

Oxygenation and Nitridization

XPS/AUGER/LEED Analysis

MBE

RHEED

MOS

SIMS

RIBE

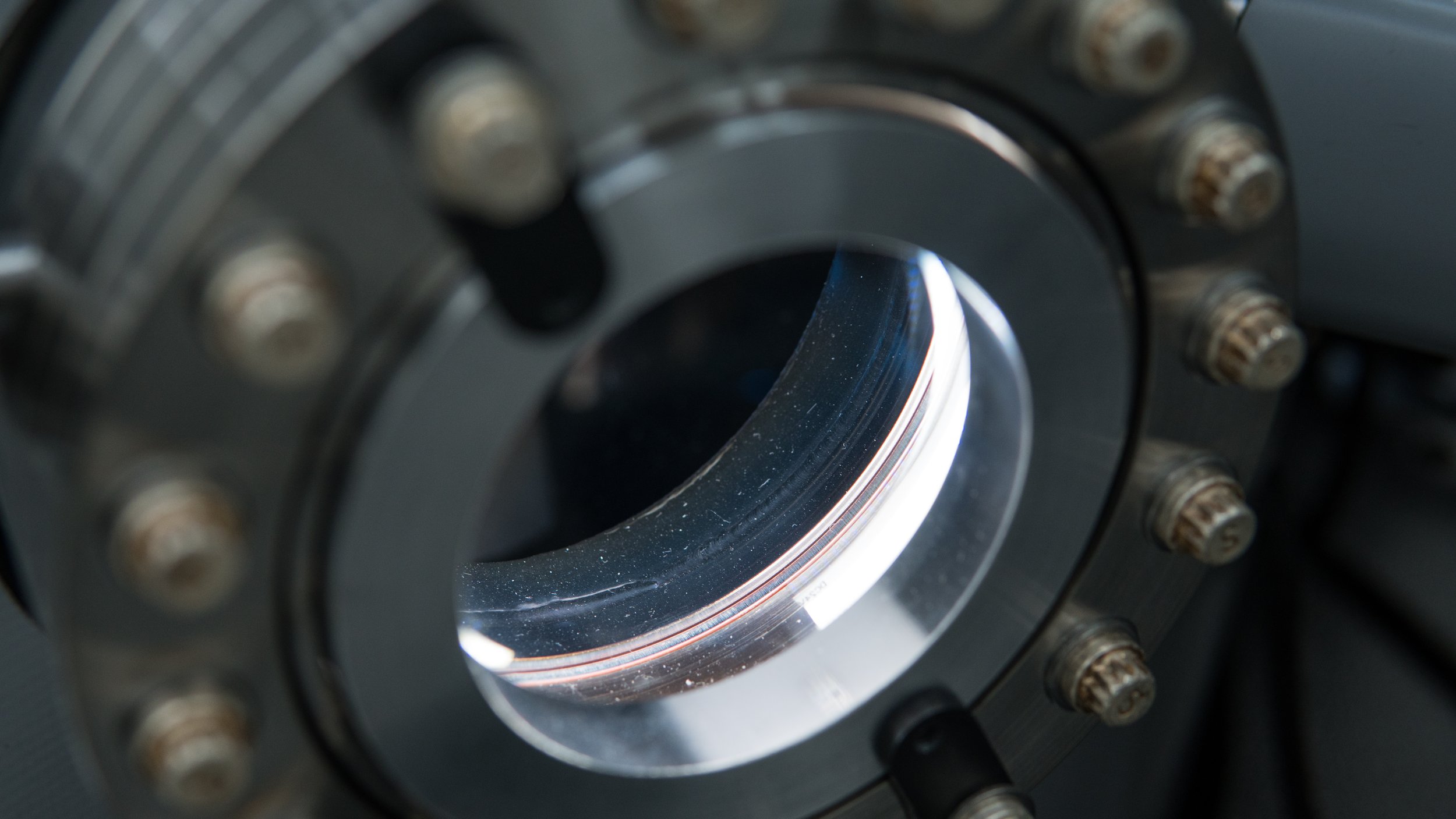

ATC-2200-HY

ATC-2200-HY UHV Hybrid Deposition System with XPS integration

The ATC-2200-HY Hybrid Deposition system is equipped with (5) 2” con-focal sputtering sources, (1) 3” direct sputtering source, (1) 6-pocket 15cc linear electron beam gun, and (1) 4cm gridded DC ion source. The system is designed to accommodate up to 3” wafer handling, 850C heating, azimuthal rotation, RF/DC biasing, 100mm z-motion, and in-situ mask exchange mechanism. In addition the system has an appendage chamber that allows the user to disengage the mask, flip the substrate 180 degrees, and in-situ transfer into an XPS system for chemical and elemental analysis.

ATC 1800-HY

Incorporates con-focal sputtering, a (6) pocket linear e-beam source, ion milling with SIMS end point detection, and a retractable sputter source for short working distance direct sputtering (e.g. Nb superconductors). This UHV tool is equipped with a +/- 200° tilting substrate holder that can be equipped with various features such as heating, cooling (LN2/H2O), rotation, and RF biasing. Additional features include load-lock oxidation, glove box integration, ellipsometry, and in-situ crucible exchange of the e-gun.

ATC-2036

Our versatile design utilizes a stainless steel box chamber with double hinged door and removeable side plates. This allows us to have these chambers readily available in stock, and are easily customizable per our customer’s requirements. Chambers can be equipped with multi-pocket electron beam sources, thermal evaporation, k-cell, and ion sources. Substrate holders can be equipped with heating, cooling (LN2/H2O), tilting, rotation, and stepper motor controlled wedge shutters.

ATC 2200-HY

The ATC-2200-HY Hybrid Deposition system is equipped with (5) 2” or (4) 3” con-focal sputtering sources, (1) 3” direct sputtering source, (1) 6-pocket 15cc linear electron beam gun, and (1) 4cm gridded DC ion source. The system is designed to accommodate up to 8” wafer handling, 1000C heating, azimuthal rotation, RF/DC biasing, 100mm z-motion. Additional features include bakeout jacket, in-situ crucible exchange, cassette loading, and substrate holders optimized for combinatorial chemistry.