Sputter Beam Epitaxy

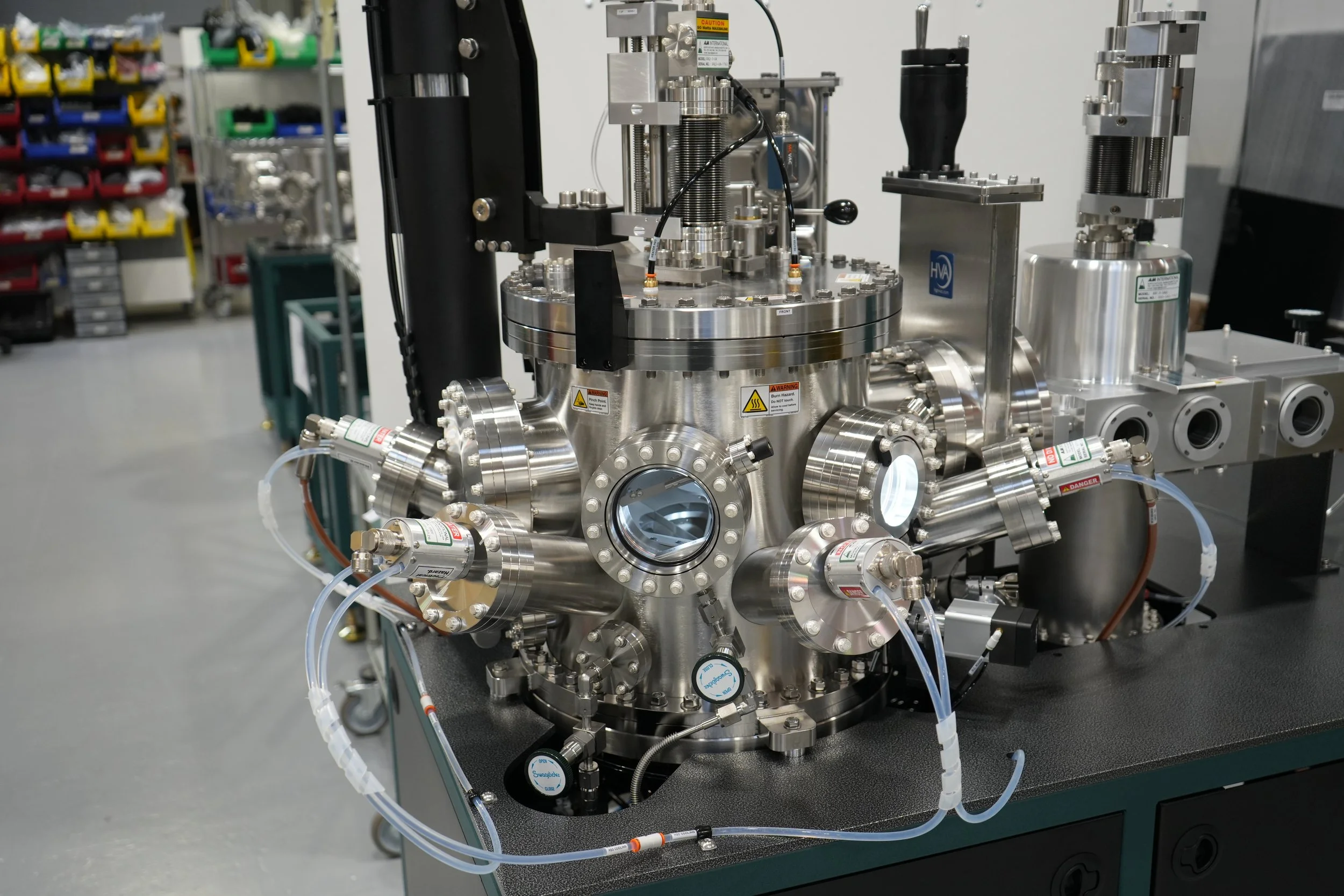

SBE-6 Series Sputter Beam Epitaxy (SBE) Deposition System

Overview

Nano-engineered materials enable discoveries in fields such as spintronics for electronic memory and logic applications, ferroelectric memories, sensors based on giant magnetoresistance or tunneling magnetoresistance (GMR and TMR), superconductors, and the like. Epitaxial thin films, with their excellent crystallographic structure and flat, atomically precise interfaces are required to explore the fundamental interactions giving rise to these phenomena and to develop corresponding applications. The SBE-6 Series Sputter Beam Epitaxy (SBE) Deposition System combines deposition quality that rivals molecular beam epitaxy (MBE) with the ease, flexibility, and lower cost of sputtering. The SBE-6 Series is positioned as a leading-edge solution in thin-film fabrication.

The SBE-6 Series was developed in collaboration with Professor Adam Hauser at the University of Alabama. In contrast to conventional "off-axis" sputtering configurations, the SBE-6 Series enables the co-deposition or sequential deposition of up to six distinct materials while minimizing cross-contamination. This advanced platform integrates years of refinement in deposition dynamics within AJA International’s proven engineering framework and high-performance components recognized globally for their reliability.

Key Features of the SBE-6 Series Sputter Beam Epitaxy System

Magnetron Sputtering Sources:

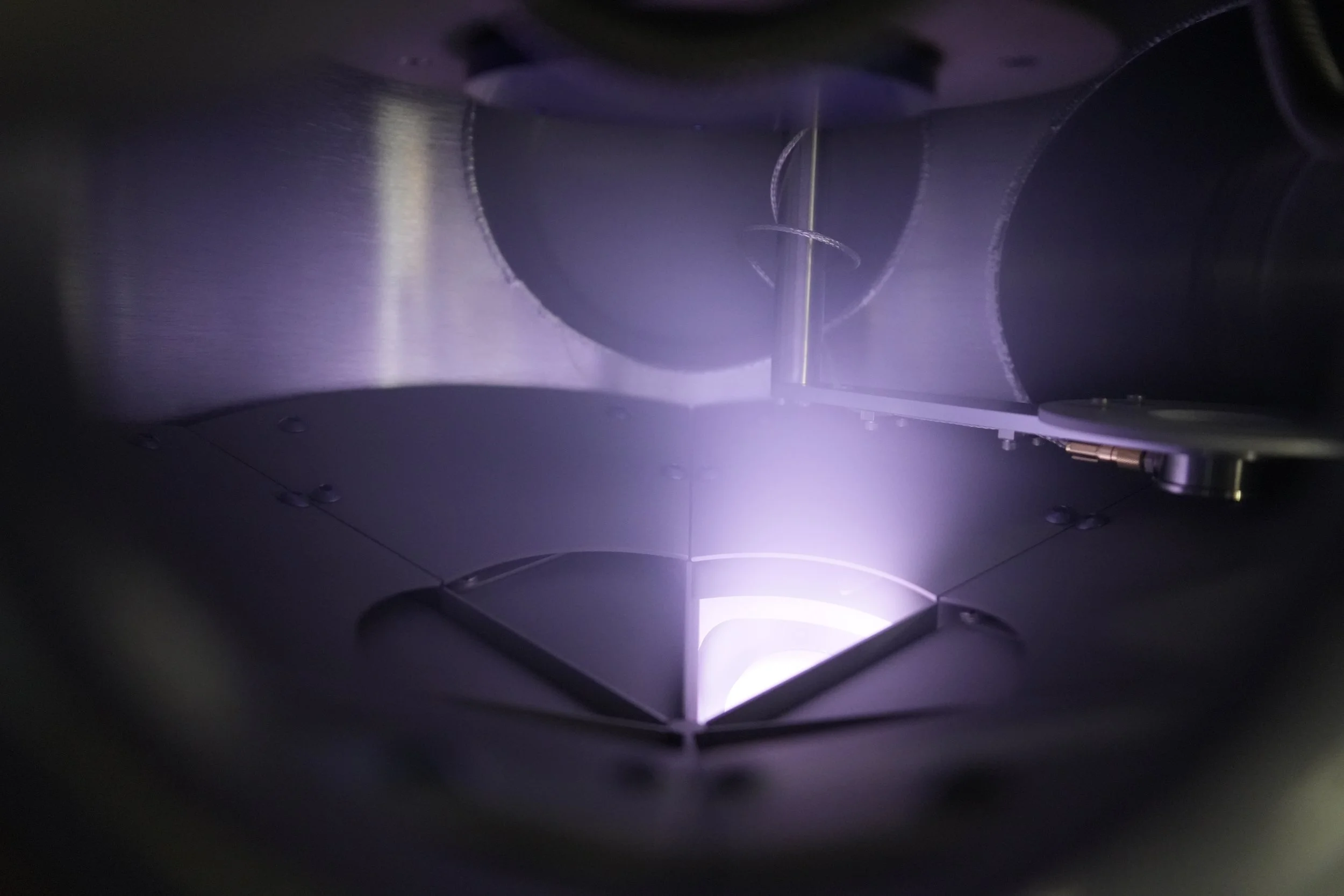

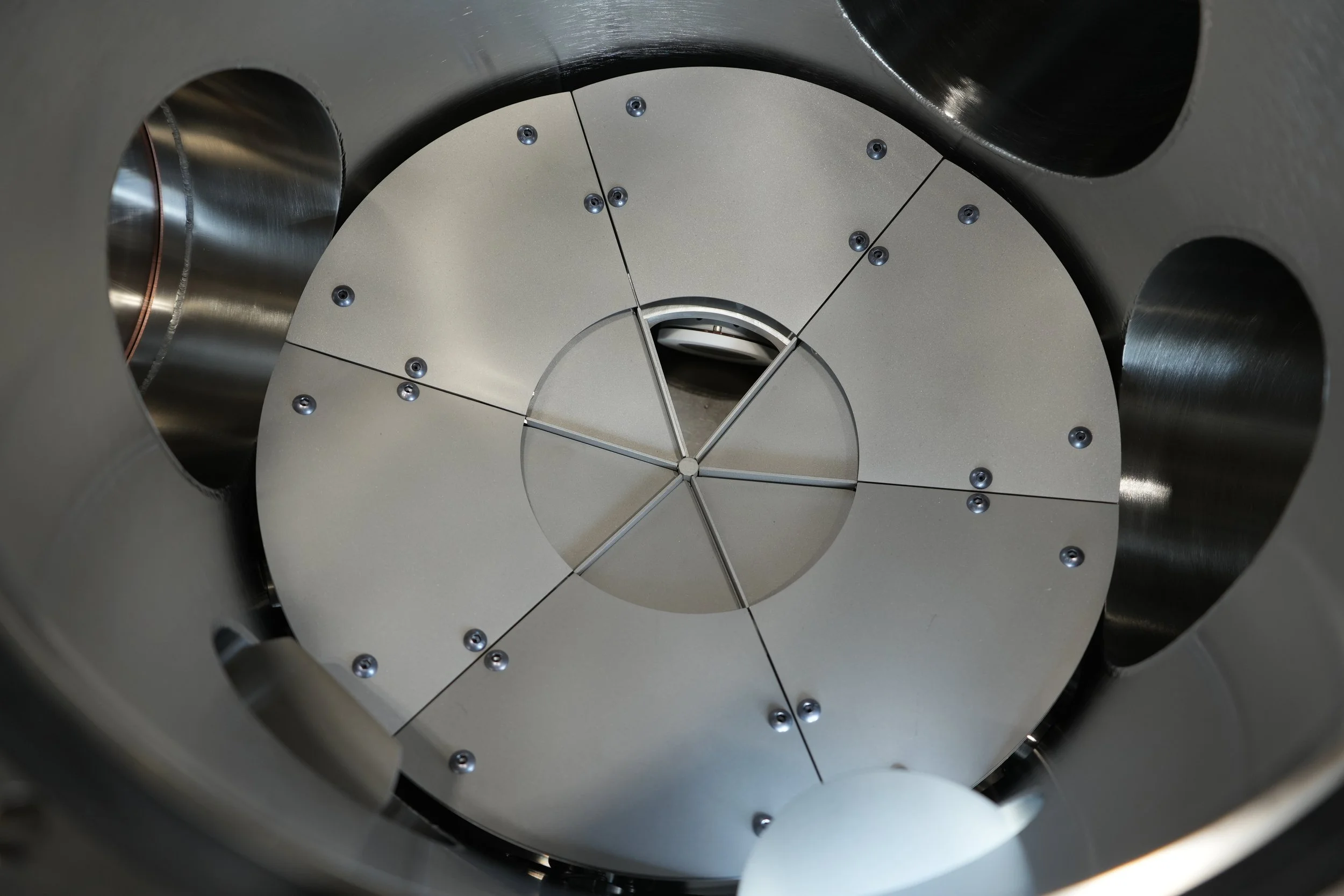

The SBE-6 system accommodates up to six 1.5” or 2” magnetron sputtering sources, each equipped with individual isolation shielding and specially designed shutters to minimize cross-contamination and enable precise control of deposition parameters. The geometry works in configuration with thoroughly researched stage positioning and substrate rotation parameters to obtain precise film stoichiometry and atomically flat interfaces.

Substrate Holder:

The substrate holder is highly configurable, supporting sample sizes ranging from small coupons to full wafers up to 4” diameter with excellent film thickness uniformity. (Speak with us about customized tools for working with larger substrates; AJA International provides configurations for wafers up to 8”.) Available functionalities include high-temperature substrate heating (up to 800–1,000 °C), cryogenic or water-based cooling (LN₂ or H₂O), azimuthal rotation for uniform film growth, motorized Z-axis motion, and RF/DC substrate biasing for advanced process control.

Power Supply Options:

DC and RF sources are preferred for sputter beam epitaxy, as they provide the lowest energy source particles, as required for atomically-ordered film growth. They further offer stability and compatibility with a wide range of materials. Any combination of up to six of these supplies can be provided for co-deposition, allowing access to a vast film stoichiometry space. AJA International does offer a comprehensive selection of power supplies, so pulsed DC and high-power impulse magnetron sputtering (HiPIMS) supply configurations can be provided to support further research into film growth dynamics.

Ultra-High Vacuum (UHV) Design:

The SBE-6 system is engineered to achieve base pressures ranging from the low 10⁻⁷ Torr to the low 10⁻¹⁰ Torr regime. Systems can be constructed using all-metal seal vacuum chambers, and in-house manufactured bakeout jackets are available for thorough vacuum conditioning and system degassing.

Process Gas Delivery:

The system supports up to four mass flow controllers (MFCs) for precise regulation of process gases. Typical gases used in epitaxial deposition include Ar, O₂, and N₂, allowing for a wide range of reactive and inert sputtering processes.

Quartz Crystal Monitor:

A quartz crystal microbalance (QCM) enables deposition rate calibration of each species, to precisely control the stoichiometry of multi-component films grown from elemental targets. This eliminates the need for costly composite targets, which are often difficult to procure. The QCM also provides real-time thickness monitoring during film growth. The system supports both manual and fully automated operation modes for precise film thickness control.

Load-Lock System:

AJA provides multiple load-lock configurations to meet varying throughput requirements, including manual and automated sample transfer mechanisms. For high-throughput applications, cassette-based systems can accommodate 2 to 10 carriers. Optional modules for sample pre-cleaning, degassing, oxidation, or in-situ analytical diagnostics can be integrated as needed.

In-Situ Analytical Capabilities:

The SBE-6 platform is compatible with a wide range of in-situ characterization tools, including reflection high-energy electron diffraction (RHEED), ellipsometry, optical emission spectroscopy (OES), pyrometry, and residual gas analysis (RGA), enabling real-time monitoring of growth conditions and film properties.

Multi-Chamber Integration:

The SBE-6 Series can be configured for multi-chamber operation, supporting direct vacuum-compatible connections with additional process modules. These may include co-focal sputtering systems, electron-beam deposition sources, or third-party equipment. Designed with future expansion in mind, the system facilitates in-situ sample transfer between chambers to preserve vacuum integrity and minimize exposure.

Performance

Professor Hauser has been developing sputter beam epitaxy and studying epitaxial thin film systems for over 15 years. Shown here are two examples of the impressive results obtained with the SBE process.

Magnetic Materials

Cobalt-based Heusler compounds are of great interest due to their potential applications in spintronic devices and shape memory technologies [1]. SBE was utilized to grow a film stack consisting of a TiN buffer layer, a Co2TiSn alloy and a Nb capping layer, on sapphire. The high flatness and homogeneity of a buffer layer grown on a-plane sapphire is evidenced by the narrow peak width and numerous, strong Laue oscillations in the X-ray diffraction (XRD) pattern. The epitaxy is further affirmed by atomic force microscopy (AFM) scan of the surface, revealing step-edge growth. See the accompanying figures.

XRD pattern of TiN buffer layer

Finally, we can observe in the XRD rocking curves of the TiN and Co2TiSn films (below) structural quality of the epitaxial growth. The peaks are far narrower than for films reported by other methods, with peak widths matching that of bulk single crystals.

AFM scan of TiN buffer layer

XRD rocking curves of layer stack

[1] Read the full article describing this research: Nahar, et. al, “Heteroepitaxy route to substrate limited epitaxial Co2TiSn thin films by sputter beam epitaxy”, Phys. Rev. Mat. 9, 024401 (2025).

Superconductors

Superconducting resonators have applications in quantum computing and microwave detection[2]. Excellent crystalline quality is required for high Q-factors. The scanning transmission electron microscopy (STEM) images below reveal the atomic order in an aluminum film and a silver capping layer grown on a sapphire substrate. The top figure shows essentially perfect ordering and interfacial flatness between the Ag capping layer (brighter) and the lower Al layer. The bottom scan shows excellent Al structure on the substrate (despite some disorder at the interface).

SBE provides thin films suitable for research and applications development into advanced devices.

Atomic resolution STEM

[2] Read the full article describing this research: Law et. al, “Demonstration of nearly pinhole‑free epitaxial aluminum thin films by sputter beam epitaxy”, Sci. Rep. 10, 18357 (2020).

The SBE-6 Series Sputter Beam Epitaxy (SBE) Deposition System represents a unique solution available from AJA International. The SBE-6 combines AJA’s trusted engineering with breakthrough deposition geometry to deliver MBE-like film quality using advanced magnetron sputtering. Its unmatched material isolation, configurability, and ultra-high vacuum performance make it the ideal platform for high-precision thin-film research and production.

To learn more about how the SBE-6 can elevate your deposition capabilities, contact our sales team today.