High Entropy Alloys

High Entropy Alloy Deposition Systems

Co-deposition of a high entropy alloy in an AJA International sputtering system.

More than 3,000 years ago, Iron Age blacksmiths were adding charcoal to iron to obtain a tougher material. However, it was not until about 200 years ago that the alloying process started to be understood. Alloying creates materials with enhanced properties, compared to the individual constituents. Stainless steel, for example, has minor amounts of other elements to provide corrosion resistance, ductility, and stability.

Traditional alloys have one major component (iron, in the example above) and up to several minor components that may only be present at the percent level. The continual desire to improve alloy properties—mechanical, electrical, magnetic, corrosion resistance and the like—has led to the investigation of more complex material systems.

High entropy alloys (HEA) are defined as mixtures of five or more elements in roughly equimolar amounts. They are named from the high entropy of mixing that exists in this configuration. If grown correctly, the high entropy stabilizes a single-phase solution (alloy) of the constituents. HEA’s have been a subject of intense research since the first paper was published about 20 years ago (2003). Favorable properties enabled or under development for these materials include:

High wear-resistance for tribological applications such as hard coatings or cutting tools

Oxidation and creep resistance for demanding applications at high temperature

High yield strength and fatigue resistance for mechanical structures

High strength-to-weight ratio for device housings and lightweight consumer products

Thermal stability and electrical conductivity for electronics

Engineered magnetic properties for high coercivity magnets

Overview

Other variants of these materials, such as high entropy nitrides, high entropy oxides, and high entropy intermetallics are being explored more recently. The sheer number of possible combinations of elements in these materials calls for great flexibility in exploring the composition space. For example, with 40 elements to work with and considering to explore just three levels of concentration for each, the number of possible combinations is above 10²³. Smart theory, combined with flexible and rapid experimentation are required to hone in on useful combinations.

Exploration with magnetron sputtering is a commonly applied, efficient method of making novel multicomponent materials such as HEA’s. A deposition system with five sputtering guns co-depositing can produce a novel material in minutes. With the further introduction of combinatorial deposition the throughput for alloy research can be increased dramatically.

Key Features of AJA Deposition Systems for High Entropy Alloys

Magnetron Sputtering Sources:

AJA International systems offer configurations for mounting several magnetrons, in either sputter up or sputter down orientation. The ATC Series can support up to 13 guns in combinations of confocal, direct, and off-axis sputtering geometries for exploring large material spaces. The Orion series can mount up to 8 guns. Co-deposition with up to 9 power supplies gives access to an extensive compositional space in creating alloys. A central substrate-facing port can also house in-situ probes for real-time monitoring and analysis. Our guns feature integral gas injection rings for local process gas delivery.

Substrate Holder:

The substrate holder is highly configurable, supporting sample sizes ranging from small coupons to full wafers up to 6” (Orion) or 12” (ATC) diameter with excellent film thickness uniformity. Available functionalities include high-temperature substrate heating (up to 800–1,000° C), cryogenic or water-based cooling (LN₂ or H₂O), substrate rotation for uniform film growth, motorized Z-axis motion, and RF/DC substrate biasing for advanced process control.

Combinatorial Substrate Holder:

AJA’s combinatorial substrate holders build upon our robust standard designs and are enhanced with UHV-compatible X/Y stepper motor-driven bellows mechanisms. These holders accommodate multiple discrete samples on a single substrate, with common configurations including 5×5 and 10×10 arrays of 5 mm specimens (25 and 100 samples, respectively). An integrated automated masking system—with interchangeable apertures—allows flexible specimen sizing and isolation. The mask assembly can be retracted for gradient film deposition or traditional confocal sputtering geometries with substrate rotation for uniform coatings.

We also offer a combinatorial chemistry deposition retrofit for Orion systems, which mounts on the central sample-facing port of the gun flange. The upgrade adds high-throughput experimentation capability to existing tools.

High Vacuum and Ultra-High Vacuum Designs:

Our systems are engineered to achieve base pressures ranging from the low 10⁻⁷ Torr to the low 10⁻¹⁰ Torr regime. Systems can be constructed using all-metal seal vacuum chambers, and in-house manufactured bakeout jackets are available for thorough vacuum conditioning and system degassing.

Deposition Recipe Generator:

The software makes it simple to create and store up to 100+ recipes for depositing layer stacks. It is easy to write extensive recipes, and the Excel spreadsheet layout allows line by line layer stacking and review of recipes for accuracy and data extraction if needed. Recipe operation automates the entire deposition process, with auto-abort in case setpoints fail to be reached. Our AJA Excel Spread Sheet Software Emulator makes possible remote recipe creation offline from the system for later import and execution. The Emulator structure is designed to allow computer model or AI-based generation of recipes, for direct insertion into the Phase II-Au operating system software. This powerfully accelerates compositional space search capabilities.

Nanometer-Precision Film Thickness Control:

An optional quartz crystal monitor and controller allows calibration of deposition rates, which is key for creating alloy films with designed compositions. High-stability power supplies provide precise, repeatable deposition rates, while recipe-driven automation ensures accurate, repeatable process execution.

Vertically Integrated System Design:

AJA International manufactures many of the components in the systems. This ensures compatibility and quality, while controlling tool costs. This also speeds up service and provides long service life for the systems.

Example ATC gun configuration

Example Orion gun configuration

Process Gas Delivery:

The system supports up to four mass flow controllers (MFCs) for precise regulation of process gases. Typical gases used include Ar, O₂, and N₂, allowing for a wide range of reactive and inert sputtering processes. Other gases can be provided. A gas ring can be included at the substrate for reactive deposition of oxides and nitrides. Non-local delivery is also available, so that all guns share the same process gas pressure.

Power Supply Options:

DC, pulsed DC, RF and HiPIMS supplies can all be configured into the system. AJA’s standard Phase II-Au control system will accommodate up to (5) DC power supplies with integral 4-way switchboxes, (4) RF power supplies, and (1) 4-way RF switchbox. This allows maximum flexibility for co-deposition from a large selection of sputter guns so that new material systems can be rapidly developed. Single target deposition from alloy targets has also been shown to provide stoichiometrically similar alloy films, for cases where simpler operation is desired.

ATC Flagship System

Performance

Professor Kai Liu and co-workers and Georgetown University have done much work in high entropy magnetic alloys. In a recent paper [1] they report results from FeCoNiMnCu sputtered alloys and (FeCoNiMnCu)Pt high entropy intermetallic films. They were able to achieve large increase the coercivity of the films and also perpendicular magnetic anisotropy (PMA). Both of these qualities are useful for devices.

For the HEA film, the sputtering was carried out from a single alloy target containing equimolar amounts of the constituent elements. Sputtering led to films with roughly the same stoichiometry (within 5%). This concurs with other work showing that HEA’s can be grown from compound targets, if a fixed composition is acceptable. They showed how rapid thermal annealing (RTA) of the films produced single-phase alloys. This was a critical step, as simply growing the films at elevated temperatures led to phase separation (fcc and bcc). First-order-reversal-curve (FORC) analysis showed a 40x increase in coercivity from the RTA treated films. They explain this as likely due to distortions or chemical ordering effects.

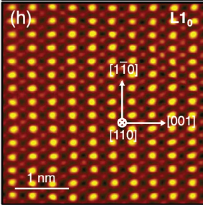

In a second experiment, co-sputtering from six targets was carried out to obtain the HEA-Pt intermetallic. Co-sputtering produced films of composition within 2% of an HEA equimolar ratio. The Pt atoms formed an ordered structure, leading to a single high entropy L1₀ phase.

FORC and magnetometry show a high degree of PMA and up to 3 orders of magnitude increase in coercivity.

STEM image of the structure

FORC measurements

This work highlights the vast material space to be discovered in HEA’s and how sputter deposition provides the flexibility to rapidly produce research and development samples. Finally, we note that their interesting work was featured on this cover of the journal (image).

[1] W. B. Beeson, D. Bista, H. Zhang, S. Krylyuk, A. V. Davydov, G. Yin, K. Liu, Single-Phase L10-Ordered High Entropy Thin Films with High Magnetic Anisotropy. Adv. Sci. 2024, 11, 2308574. https://doi.org/10.1002/advs.202308574

[2] see for example https://is.mpg.de/mms/de/projects/first-order-reversal-curves

AJA International’s Orion and ATC Series Deposition Systems provide high flexibility and customization options for advanced film studies. The ability to run multiple guns, grow compounds reactively, and characterize the plasma ions elucidates the connection between growth conditions and film performance.

To explore how AJA systems can advance your materials science research, contact our sales team today.