High Power Impulse Magnetron Sputtering (HiPIMS)

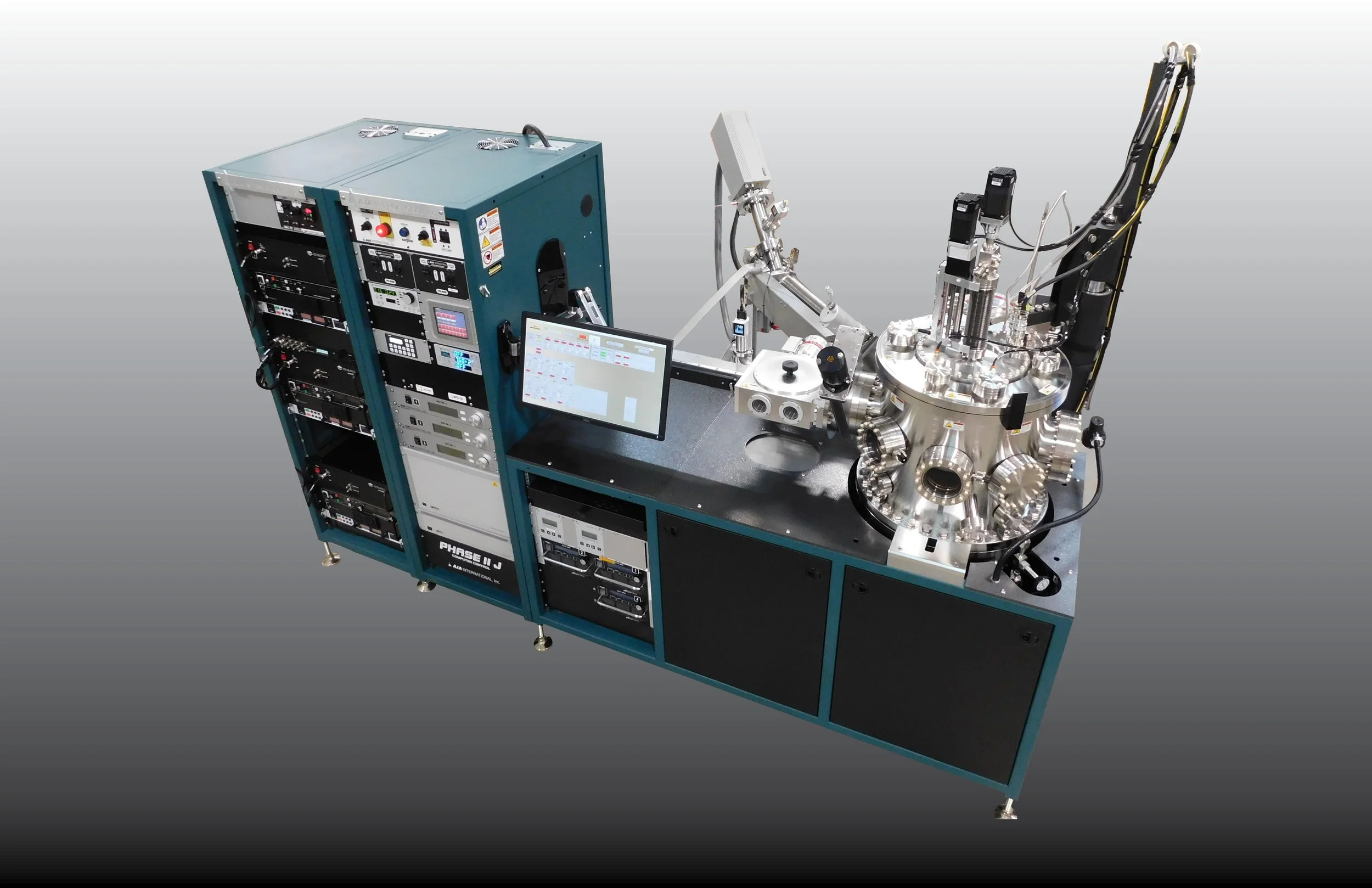

HiPIMS Deposition Systems

Overview

Magnetron sputtering is a workhorse method for depositing thin films. It can operate with a wide variety of source materials (targets), with great flexibility and simplicity. By creating a process gas plasma over the target, sputtering takes place, transferring material from target to substrate being coated. In conventional (DC or RF) sputtering the plasma density is limited, which in turn narrows the range of accessible deposition parameters.

In High Power Impulse Magnetron Sputtering (HiPIMS) the plasma power is delivered in intense, short pulses (µsec length with kW/cm2 instantaneous power density). This produces a large amount of sputtering during the pulse, and – more importantly – a large degree of ionization of the sputtered atoms. These ionized species can now be accelerated toward the substrate surface to create a variety of beneficial effects. We give here a few examples:

Energetic ions (tens of eV) add energy to the growing film, allowing atoms to settle into better epitaxial order. Ionized species also promote reactive deposition.

At the substrate interface, greater acceleration permits implantation that aids film adhesion and densification.

Acceleration collimates the flux, which can help direct it into 3D structures, improving step coverage in, for example, high-aspect ratio trenches.

The timing of the pulses can be arranged to selectively accelerate certain species over others. Accelerating pulses can be provided by the power supply itself (reverse bias for bipolar HiPIMS) or by substrate bias.

The latitude provided by arranging the pulsing greatly increases process flexibility, hence imparting greater material growth options. Since the average power is still moderate, HiPIMS can be practiced using standard magnetrons. Only the power supply needs to be changed. Deposition rates are typically less than for DC sputtering, but much work has gone into improving this. HiPIMS is being applied successfully to address a variety of challenges: tribological (hard) coatings, diamond-like carbon, conformal coatings, optics, functional electronic coatings – among others. AJA International Orion and ATC Series sputtering systems are designed to seamlessly integrate HiPIMS technology, giving materials scientists numerous options for advanced thin film development.

Key Features of the Orion and ATC Sputtering Systems for HiPIMS

Magnetron Sputtering Sources:

Each system offers configurations for mounting several magnetrons, in either sputter up or sputter down configurations. The ATC Series can support up to 13 guns in combinations of confocal, direct, and off-axis sputtering geometries for exploring large material spaces and for completing devices with a selection of capping and electrical lead options. The guns feature integral gas injection rings for local process gas delivery. This allows great freedom in exploring composition space and complex device architectures. Magnetrons are available for both high vacuum (Stiletto Series) and ultra-high vacuum (A300 Series) applications.

Our guns magnet arrays are modular and can be exchanged in the field, allowing the user to switch between balanced, unbalanced, and magnetic material modes depending on the application.

Unbalanced HiPIMS Co-Sputtering

(photo credit: EMPA)

Analytical Options:

An optional quartz crystal monitor and controller allows calibration of deposition rates. Other add-ons such as RHEED, ellipsometry, energy analyzers, stress analysis, and others allow for thorough characterization of both deposition dynamics and the resulting films. Sufficient spare ports are provided for measurement devices the user may desire to incorporate.

Substrate Holder:

The substrate holder is highly configurable, supporting sample sizes ranging from small coupons to full wafers up to 6” (Orion) or 12” (ATC) diameter with excellent film thickness uniformity. Available functionalities include high-temperature substrate heating (up to 800–1,000 °C), cryogenic or water-based cooling (LN₂ or H₂O), azimuthal rotation for uniform film growth, and motorized Z-axis motion. RF/DC substrate biasing provides advanced process control that can be synchronized with the HiPIMS pulsing, in order to further control the deposited ion energy.

Process Gas Delivery:

The system supports up to four mass flow controllers (MFCs) for precise regulation of process gases. Typical gases used in epitaxial deposition include Ar, O₂, and N₂, allowing for a wide range of inert and reactive sputtering processes. A gas ring can be provided at the substrate for reactive deposition of oxides and nitrides. Other process gases are supported, as well, per customer request.

Deposition Recipe Generator:

Recipe-driven automation ensures accurate, repeatable process execution. The software makes it simple to create and store up to 100+ recipes for depositing layer stacks such as superlattices. It is easy to write extensive recipes, and the Excel spreadsheet layout allows line by line layer stacking and review of recipes for accuracy and data extraction if needed. Recipe operation automates the entire deposition process, with auto-abort in case setpoints fail to be reached. Our AJA Excel Spread Sheet Software Emulator makes possible remote recipe creation offline from the system for later import and execution.

Vertically Integrated System Design:

AJA International manufactures many of the components in the systems. This ensures compatibility and quality, while controlling tool costs. This also speeds up service and provides long service life for the systems.

Power Supply Options:

DC, pulsed DC, RF and HiPIMS supplies can all be configured into the system. AJA’s standard Phase II-Au control system will accommodate up to (5) DC power supplies with integral 4-way switchboxes, (4) RF power supplies, and (1) 4-way RF switchbox. High-stability power supplies provide precise, repeatable deposition. Multiple HiPIMS supplies can run simultaneously in unipolar or bipolar mode, with the option of adding a synchronization unit to time the pulses for simultaneous or fixed delay firing.

Performance

Dr. Sebastian Siol’s Coatings Technology Team at the Swiss Federal Laboratories for Materials Science and Technology (Empa) has done work showcasing the level of material growth control possible with HiPIMS. They set out to develop thin film aluminum scandium nitride (AlScN) with excellent texture and crystallinity. AlScN in wurtzite structure is used in RF-MEMS and ferroelectric applications. Its performance is tightly coupled with its structural properties, in particular the texture. Conventionally high quality AlScN thin films are grown at very high temperatures, but this limits the compatibility with common semiconductor manufacturing processes and temperature sensitive substrates.

HiPIMS offers the promise to grow high-quality thin films at moderate temperatures, due to the higher kinetic energy of the sputtered particles. In addition, HiPIMS offers very high ionized flux-fractions when compared to conventional sputtering techniques.

As an Ionized Physical Vapor Deposition (IPVD) technique, HiPIMS offers the ability to accelerate the sputtered species, which are charged, with the help of substrate bias potentials, in order to add energy to the growing film. This enhances adatom mobility, promoting atoms into lattice sites. However, real-world technological substrates are often electrically isolated, precluding the application of bias or use of reverse pulses (bipolar mode) that would normally provide the ion acceleration. Bias can be indiscriminate as well, driving Argon process gas atoms into the films and producing defects.

Dr. Siol’s team devised an innovative HiPIMS-based technique[1] that relies on precisely-timed synchronized pulses from three separate magnetrons. When sputtering from unbalanced magnetrons the substrate gets immersed in the sputter plasma during the HiPIMS discharge. This provides a temporary negative self-bias to the electrically floating substrate surface. The new technique, dubbed Synchronized Floating Potential (SFP) HiPIMS, makes use of this transient negative potential to provide tailored acceleration to specific ions. In their study, the voltage pulses from three HiPSTER 1 (Ionautics) power supplies were coordinated by a single HiPSTER Sync Unit. Through carefully timed pulses based on time-resolved ion energy spectra, they were able to accelerate the scandium ions from using the floating potential induced by the discharge of the aluminum guns. In addition, the researchers leveraged the different time of flight for the Ar and Sc ions following each Sc discharge. The timing of the Al discharge was optimized such that the faster argon ions were not accelerated nearly as much as the slower scandium. This helps to grow high-quality textured thin films, while simultaneously avoiding process gas incorporation as much as possible. Finally, by doing the deposition reactively from elemental targets, the stoichiometry could be precisely controlled, producing 12% doped (Al0.88Sc0.12N) films.

The result of leveraging all the degrees of freedom available in HiPIMS was a deposited material with better epitaxy and negligible stress and no measurable argon contamination when compared to a conventional sputter process. The HR-TEM image and FFT patterns (insets) reveal the quality of the film growth. All these properties were obtained on an electrically floating substrate at low deposition temperature (100°C).

These benefits directly impact device performance. Recently the team demonstrated the low-temperature HiPIMS deposition of ferroelectric AlScN with performance normally only observed in epitaxial films grown by MBE or MOCVD techniques.[2]

HR-TEM of AlScN on sapphire

Read more on Dr. Siol’s work here:

[1] Patidar, J., Pshyk, O., Thorwarth, K., Sommerhäuser, L., & Siol, S. (2025). Low temperature deposition of functional thin films on insulating substrates enabled by selective ion acceleration using synchronized floating potential HiPIMS. Nature Communications, 16(1), 4719.

https://phys.org/news/2025-06-electron-shower-technique-advanced-piezoelectric.html

AJA International’s Orion and ATC Series Deposition Systems provide high flexibility and customization options for advanced film growth by HiPIMS. The ability to run multiple pulse-synchronized guns, grow compounds reactively, configure the gun plasma confinement, and tailor the impact energy of the various species all highlight the design of the systems to support complex growth modes for important functional materials. Please inquire for summaries of other applications that are enabled by this technique.

To explore how AJA systems can advance your materials science research with HiPIMS, contact our sales team today.