Thin Film Nitrides

Reactive Deposition in Orion and ATC Sputtering Systems

Silicon dioxide (blue), titanium (gray) and titanium nitride (gold) coatings

Overview

Have you considered that gold-colored drill bit in your tool box? A titanium nitride coating gives it wear resistance. How about that smoky gray coating on your kitchen faucet? That color comes from chromium nitride. Consider also that the lightweight and compact – yet higher power – electrical charger you have relies on gallium nitride films. Nitrides are a class of compounds with a variety of useful properties. Deposition in thin film form allows coatings to be formed on almost any surface, imparting new functionalities.

Let’s look briefly at some examples, to give a better understanding of these fascinating materials.

Titanium Nitride (TiN) has a high hardness for wear-resistant coatings, good electrical conductivity (it is used in semiconductors as a conductive barrier layer), and a strong gold color that recommends it for decorative coatings.

Chromium Nitride (CrN) has high abrasion and corrosion resistance and is used in a variety of wear-intensive applications. Half of the hardest known materials are nitrides.

Aluminum Nitride (AlN) has a unique combination of very high electrical insulation while also offering high thermal conduction. It is used as a heat sink material in high-power electronics and in high-temperature applications. Nitrides rank high for thermal stability and oxidation resistance.

Gallium Nitride (GaN) is the most widely used III-V semiconductor. It is used in power electronics and is also the basis for the blue light LED.

The range of properties from this class of materials is impressive. However, sputter deposition from compound targets can be challenging. The sputtering yields and hence growth rates are low. Targets are more expensive. Some nitrides require RF sputtering, which further slows the process. Stoichiometric transfer is also an issue, i.e. the film does not have the same stoichiometry as the target. For these reasons, reactive sputtering may be practiced to make coatings of these materials.

In reactive sputtering, the target is made of the metal only. Thus, it sputters well. Nitrogen is injected to the system, and the nitride is formed reactively on the substrate as it grows. Although there are a wide variety of techniques to realize a good nitride coating, we summarize briefly some key points. To maintain a metallic target surface, a low percentage of nitrogen is often used in the sputtering gas. For the same reason, is preferable to introduce nitrogen at the substrate rather than at the sputtering source. Thus, the gas distribution must accommodate different delivery points. To promote the reaction, RF bias can be applied to the substrate. This increases the ionization fraction of the N₂, making it more reactive. The RF bias also adds energy to the growing film, promoting the proper crystalline orientation. Finally, substrate heating can be applied to anneal the structure and promote the nitriding reaction [2].

Orion Sputtering System

Key Features of the Orion and ATC Sputtering Systems for Nitrides

Magnetron Sputtering Sources:

Each system offers configurations for mounting several magnetrons, in either sputter up or sputter down configurations. The Orion Series can support up to 8 guns in combinations of confocal, direct, and off-axis sputtering geometries for exploring large material spaces and for completing devices with a selection of capping and electrical lead options. Magnetrons are available for both high vacuum (Stiletto Series) and ultra-high vacuum (A300 Series) applications.

Our guns’ magnet arrays are modular and can be exchanged in the field, allowing the user to switch between balanced, unbalanced, and magnetic material modes depending on the application.

Process Gas Delivery:

AJA’s sputtering guns have integral gas injection rings to deliver process gases (Argon and reactive species) directly to the gun. This allows operation at lower pressure with good stability. For many reactive processes, where target poisoning (compound formation) is an issue, the reactive gas can instead be delivered local to the substrate by a gas distributor. These are designed to ensure uniform gas delivery across the substrate. Gas also can be delivered non-locally or through just one gun, so that all processes use the same feed. The standard system supports up to four mass flow controllers (MFCs) for precise regulation of process gases.

Power Supply Options:

DC, pulsed DC, RF and HiPIMS supplies can all be configured into the system. AJA’s standard Phase II-Au control system will accommodate up to (5) DC power supplies with integral 4-way switchboxes, (4) RF power supplies, and (1) 4-way RF switchbox. High-stability power supplies provide precise, repeatable deposition. Multiple HiPIMS supplies can run simultaneously in unipolar or bipolar mode, with the option of adding a synchronization unit to time the pulses for simultaneous or fixed delay firing.

Analytical Options:

An optional quartz crystal monitor and controller allows calibration of deposition rates. Other add-ons such as RHEED, ellipsometry, energy analyzers, stress analysis, and others allow for thorough characterization of both deposition dynamics and the resulting films. Ellipsometry and stress analysis are particularly relevant for growing nitride films. Sufficient spare ports are provided for measurement devices the user may desire to incorporate.

Substrate Holder:

The substrate holder is highly configurable, supporting sample sizes ranging from small coupons to full wafers up to 6” (Orion) or 12” (ATC) diameter with excellent film thickness uniformity. Available functionalities include high-temperature substrate heating (up to 800–1,000 °C), cryogenic or water-based cooling (LN₂ or H₂O), azimuthal rotation for uniform film growth, and motorized Z-axis motion.

RF/DC substrate biasing:

Substrate bias has been found to be particularly important for reactive growth of high-quality nitride films, promoting the reaction and proper texturing of the films. We have found that RF bias can be more important than substrate temperature in achieving TiN films with good electrical and optical properties, for example. DC bias also promotes densification of growing films.

Deposition Recipe Generator:

Recipe-driven automation ensures accurate, repeatable process execution. The software makes it simple to create and store up to 100+ recipes for depositing layer stacks such as superlattices. It is easy to write extensive recipes, and the Excel spreadsheet layout allows line by line layer stacking and review of recipes for accuracy and data extraction if needed. Recipe operation automates the entire deposition process, with auto-abort in case setpoints fail to be reached. Our AJA Excel Spread Sheet Software Emulator makes possible remote recipe creation offline from the system for later import and execution.

Vertically Integrated System Design:

AJA International manufactures many of the components in the systems. This ensures compatibility and quality, while controlling tool costs. This also speeds up service and provides long service life for the systems.

Performance

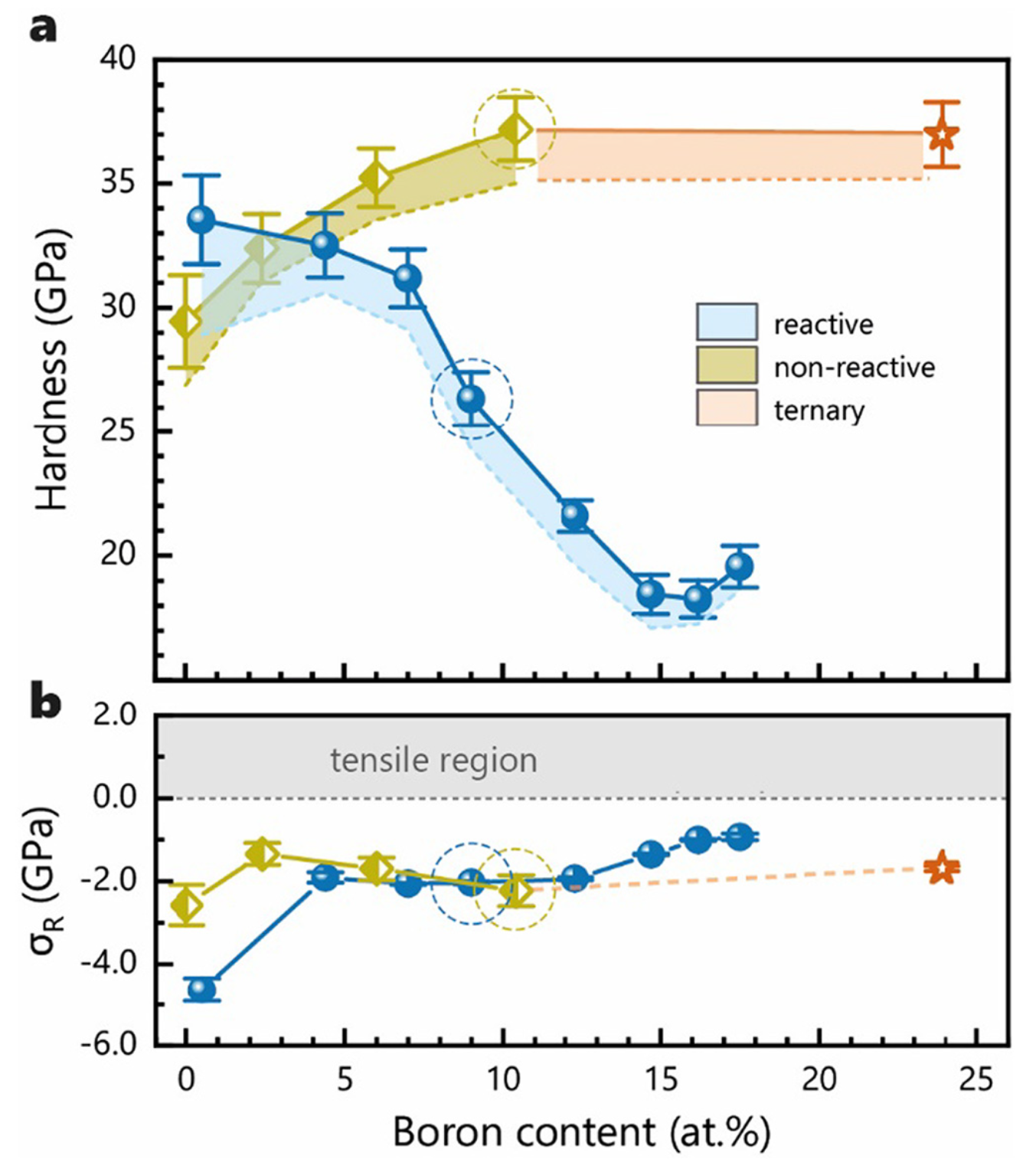

An excellent example of sputtered nitride film growth and characterization is seen in a thorough and insightful study [1] by Dr. Rainer Hahn and co-workers at TU Wien (Austria). Using an AJA International Orion 5 sputter deposition system, they explored film hardness in the titanium-boron-nitrogen (Ti-B-N) system. They compared composition and hardness of films grown reactively vs. non-reactively. A combination of DC and pulsed DC sputtering on multiple targets was applied to access different phases in this ternary system. Further, DC bias on the heated substrate (480°C) achieved a dense microstructure in the films.

They discovered that the fraction of N+ ions in the discharge determines if the bond character with increasing B concentration trends toward B–N or Ti–B. Specifically, in reactive deposition with a gas flow containing 30% N₂, the ion fraction N⁺/(N⁺ + N₂⁺) was only 15% (over-supply of less reactive N₂⁺), as compared to 51% for non-reactive deposition. This over-supply led to lower deposition rates and also toward increased B–N bonding and lower hardness. The ternary phase diagram below shows clearly how reactive deposition trended toward BN, while non-reactive trended toward TiB₂.

While both types of films showed compressive stress, the non-reactively sputtered films with stronger Ti–B bond character demonstrated higher hardness. These films also trended toward the hardness of a ternary compound.

It can be seen in this work that careful control of deposition parameters afforded by Orion system permits mapping out important sections of this three-element system for pursuing “superhard” films (hardness > 40 GPa).

[1] Read the full article describing this research: R. Hahn et al., Phase formation and mechanical properties of reactively and non-reactively sputtered Ti-B-N hard coatings, Surface & Coatings Technology 420 (2021) 127327.

https://www.sciencedirect.com/science/article/pii/S0257897221005016

[2] A recipe that we found successful for depositing TiN at room temperature is as follows: DC sputtering at 150 W with a 2” target across a 4” substrate, 3 mTorr total process pressure with 3.5% N₂ introduced at the substrate (2 sccm flow), and 50 W RF substrate bias.

Ternary phase diagram of the Ti–B–N system

Hardness and stress in the films vs. boron content.

AJA International’s Orion and ATC Series Deposition Systems provide high flexibility and customization options for advanced film studies. The ability to run multiple guns, grow compounds reactively, and characterize the plasma ions elucidates the connection between growth conditions and film performance.

To explore how AJA systems can advance your materials science research, contact our sales team today.