Mechanical Pumps

NAVAC Dry Vacuum Pumps

AJA International offers NAVAC vacuum pump solutions to support a wide range of laboratory, industrial, and research applications. With options for both oil-sealed rotary vane and oil-free dry screw designs, NAVAC pumps deliver reliable performance at an economical price point.

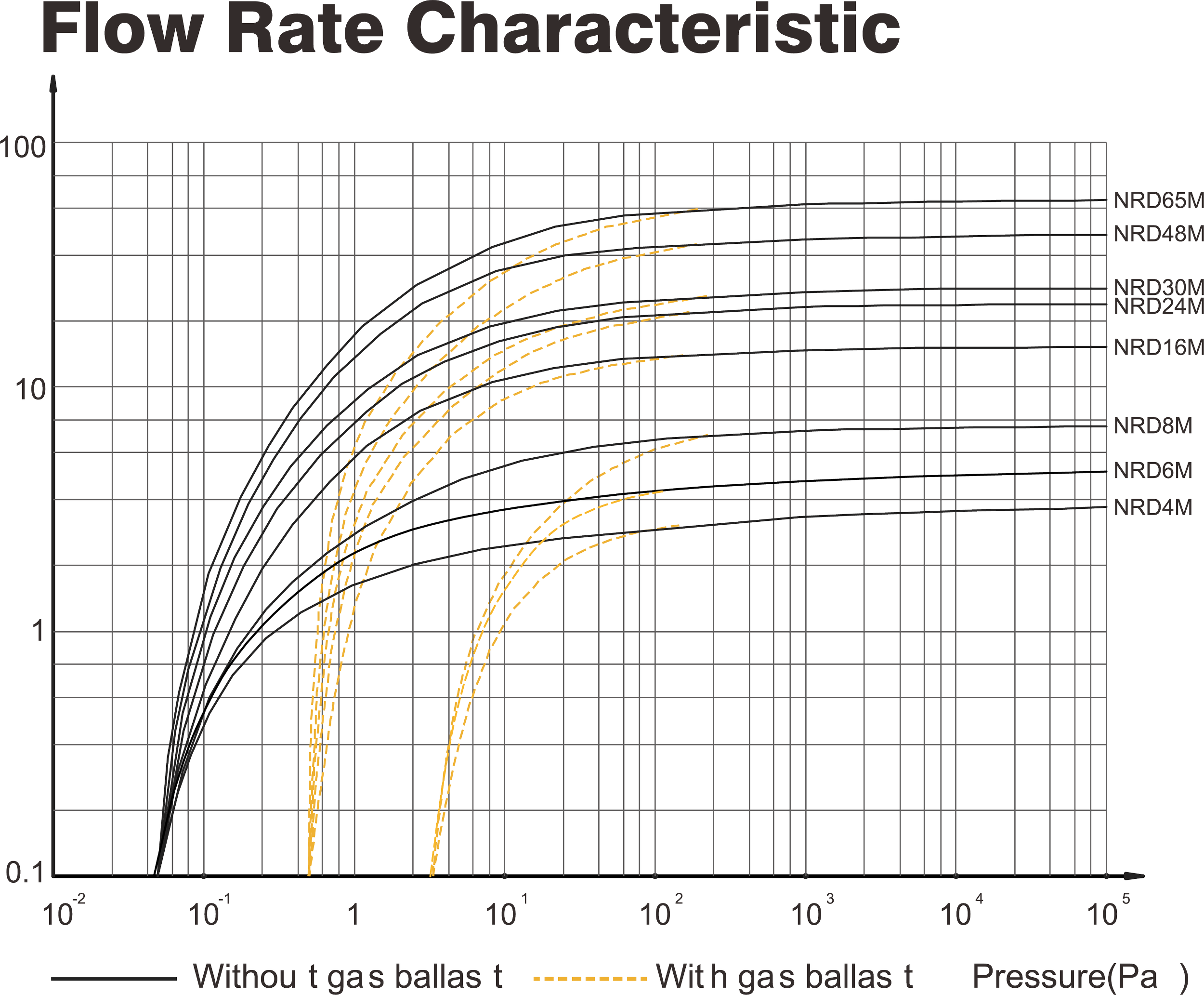

NAVAC NRD M – Dual-Stage Oil-Sealed Rotary Vane Pumps

The NAVAC NRD M series is a compact, dual-stage rotary vane vacuum pump designed to deliver stable, efficient, and reliable performance for laboratory, research, and industrial applications. With features such as a forced oil circulation system, integrated anti-suckback valve, and convenient oil inspection window, the NRD M series combines durability and ease of maintenance in an economical package.

Key Features

Dual-stage oil-sealed rotary vane design — delivers high ultimate vacuum and stable operation

Built-in anti-suckback valve — prevents oil backflow and chamber contamination during shutdown

Gas ballast function — enhances water vapor handling capability

Clear oil sight glass — easy oil level monitoring and maintenance

Compact and lightweight — ideal for benchtop or integrated system use

Low noise and vibration — quiet, smooth operation

Forced oil circulation system — ensures consistent lubrication and long service life

Applications

Thin film deposition systems (sputtering, evaporation, CVD)

Analytical and research instruments

Laboratory and industrial vacuum processes

General-purpose vacuum support and roughing operations

NAVAC HD20 HelixDrive Dry Screw Pump

The HD20 HelixDrive is an oil-free dry screw pump engineered for clean, high-throughput applications. With a 20 m³/h pumping speed and ultimate pressure down to 1×10⁻⁴ mbar (~0.01 Pa), it is ideal for thin film, semiconductor, and R&D processes where oil contamination cannot be tolerated.

Key Features

Oil-free HelixDrive screw design – no risk of oil backstreaming

High pumping capacity – 20 m³/h (12 CFM) supports larger systems

Quiet operation – noise level ≤ 60 dB(A)

Rugged and reliable – durable coatings and thermal management for long service life

Compact footprint – easy to install and integrate into vacuum systems

Low maintenance – no oil changes or disposables required

Technical Specifications

Pumping Speed: 20 m³/h (12 CFM)

Ultimate Pressure: 1×10⁻⁴ mbar (~0.01 Pa) (gas ballast off)

Inlet/Outlet: KF25 (NW25)

Weight: 48 kg

Noise Level: ≤ 60 dB(A)

Power Consumption: ~0.75 kW

Applications

Thin film deposition – sputtering, evaporation, CVD systems

Semiconductor manufacturing – contamination-sensitive process environments

Industrial R&D – pilot lines, clean labs, and research systems

Backing pump – supports turbomolecular or booster pumps in high-vacuum setups