Shop now using element filters below.

Evaporation Materials

Electron beam and thermal evaporation are adjacent techniques that are suitable for a wide variety of materials. It allows deposition of low melting-point materials that are not recommended for sputtering, but even refractory materials like tungsten can be deposited by the high-power electron beam technique. Evaporation offers the benefits of a very low energy, directed flux of material which can be delivered at lower vacuum levels. Thermal evaporation is a low-cost technique, as well.

AJA International’s shop offers a wide range of materials: metal, alloys, and compounds in a variety of forms. Our material is sold worldwide to labs for a variety of applications.

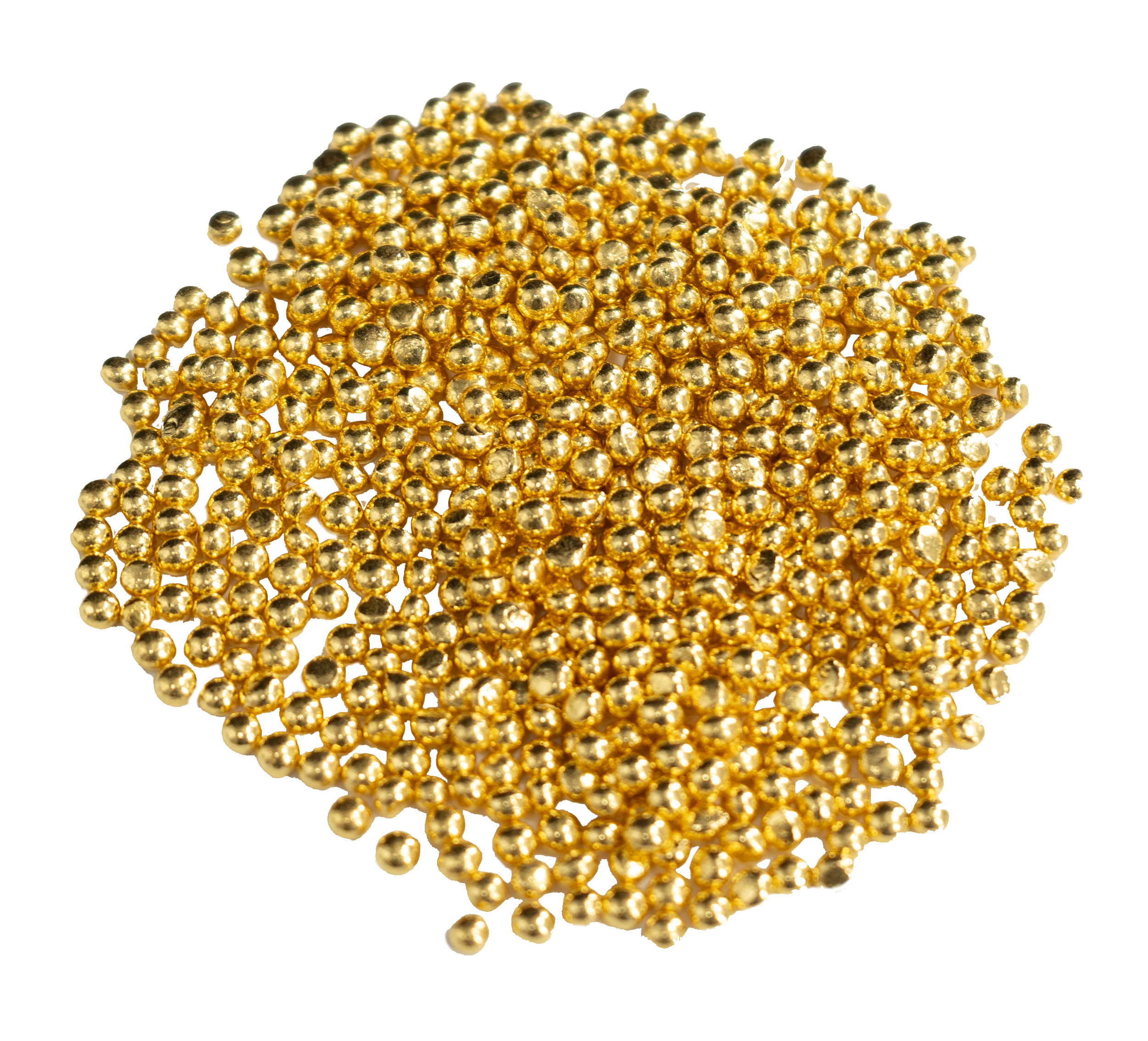

Evaporation material is offered in pellet, rod and starter (slug) forms in a range of sizes and of purity from 99.9 – 99.999% (3N – 5N).

Shop for materials from the alphabetical menu above. A price request link for special order materials is available below the materials list.

Pellets

Rods

Starters (slugs)

Fabrication Options

Sulfides

Carbides

Alloys

Pure Metals

Non-Metals

Types of Materials

Oxides

Borides

Nitrides

Selenides

Fluorides

Silicides

Evaporation Crucible Liners and Boats

Inserting a removable liner into the crucible of an electron beam evaporator allows spent material to be removed and a new charge to be added without cross-contamination. This is crucial unless the pocket is dedicated to one particular material – which is not the case for R&D systems. The liner type should be chosen for compatibility with the material being deposited. Consult with us for recommendations.

Thermal evaporation boats are selected for the material being deposited (temperature range and material compatibility), the capacity, and the form factor. The boat must be able to be heated to the required temperature by electrical current and must not react or alloy with the material.

Need evaporation crucible liners and boats? Reach out to our sales team below: